- The third-generation digital sulfuric acid APP has been officially launched

Dear users of the Digital Sulfuric Acid APP:

On May 26, 2025, our company successfully released the second generation V1.2 of the Digital Sulfuric Acid APP at the "2025 Sulfuric Acid Industry Annual Conference". The updated functions have received unanimous praise from the majority of users! During in-depth communication with on-site users, we not only deeply felt their recognition and expectations for digital sulfuric acid, but also collected numerous detailed suggestions regarding functional optimization. These valuable feedbacks will serve as an important guide for us to continuously optimize our products and enhance user experience.

At the upcoming "44th China Sulfuric Acid Technology Annual Conference", we will meet you again with a brand-new third-generation APP version that is more mature and user-friendly!

① Material balance function

Based on the original sulfur balance chart, a new sulfur-water vapor balance chart has been added. To simplify the operation mode, the concept of "standard value" has been removed, and dual formula derivation has been introduced to provide you with more flexible data simulation capabilities to meet the scene requirements of different users.

②KPI indicator function

It aims to enable you to have an intuitive grasp of the core information throughout the entire sulfuric acid production process. The presentation of index information is more intuitive, management is more convenient, and the health status and operational economy of the equipment can be monitored in real time.

③ Driving navigation function

Focus on the process safety management of the start-up of the equipment to ensure zero accidents occur during the start-up of the equipment. According to the process flow characteristics of the sulfuric acid plant, the corresponding start-up conditions can be provided, and a complete start-up navigation system can be customized in combination with the actual operation key points and indicators.

④ Real-time monitoring function

Not only can it enable you to keep track of the operation status of the device and detailed real-time DCS data anytime and anywhere through your mobile phone, but it can also clean the operation data and, in combination with the material balance function, issue fault warnings for the device's operation status and guide and train new employees, thereby shortening the training time for new employees.

To easily grasp the functional features and practical tips of the new version, we recommend that you carefully read the detailed functional explanations below!

(1) Material balance

1.1 Add a sulfur-water vapor equilibrium diagram

The sulfur equilibrium diagram shows the entire process from the combustion of liquid sulfur to sulfur dioxide, which then reacts with oxygen under the action of a catalyst to form sulfur trioxide and is ultimately converted into sulfuric acid through the contact method. The sulfur-water vapor balance diagram visually presents the process of desalinated water being converted into medium and low-pressure steam during the operation of the device.

.jpg)

Figure 1.1 Sulfur-water vapor equilibrium diagram

1.2 Simplified operation mode

Considering that users often need to adjust multiple points during operation, due to the lack of effective status identifiers, it is difficult to track the progress of modifications. Therefore, we have classified the point status on the device diagram into three states: unmodified (white background with green text), modified (green background with white text; if the modified status value remains the same as before, it will change to the unmodified state), and unmodifiable (gray background with white text). The color will no longer change due to the diagnostic results of the workbench. (See Figure 1.1 sulfur-water vapor equilibrium diagram)

Through functional reengineering, the device diagram and the workbench have achieved a separation of responsibilities: the device diagram is responsible for parameter input and formula calculation triggering functions, while the workbench focuses on the visualization and in-depth analysis of data results, making the functional structure clearer and user operations more focused.

1.3 Add double formula derivation

To meet the actual demand for flexible deduction of SO?, SO?, O?, the temperature of the flue gas discharged from the sulfur-burning furnace, the outlet temperature of each section of the converter, and the conversion rate, a more open calculation logic is now supported.

In the sulfur-burning furnace

Given the load of the device and setting the SO? concentration, the flue gas temperature of the sulfur-burning furnace can be calculated

< = >

Knowing the load of the device, set the flue gas temperature of the sulfur-burning furnace, and the concentration of SO? can be calculated

In the converter:

Knowing the concentration of the inlet gas and the inlet temperature of the conversion bed, and setting the outlet temperature, the conversion rate can be calculated

< = >

Knowing the concentration of the inlet gas and the inlet temperature of the conversion bed, and setting the conversion rate, the outlet temperature can be calculated

.jpg)

Figure 1.2 Derivation of the double formula taking the sulfur-burning furnace as an example

(II) KPI Indicators

This function showcases the three major economic indicators that users are most concerned about:

The core economic indicators display load, sulfur consumption, electricity consumption, medium-pressure steam production rate, low-pressure steam production rate, steam production rate and water consumption.

2. The conversion health diagnosis shows the temperature difference of each section of the converter, the outlet gas concentration, the total conversion rate, the layer resistance and the tail SO?.

3. Key operation indicators display acid concentration, pressure, outlet temperature, liquid level and other operation data.

Through the visual and centralized display of KPI indicators, users can fully grasp the operating status of the device and gain a clear understanding of its operation.

(The data displayed by the KPI indicators are all derived from the data calculated by formulas in the material Balance - simulation diagnosis.)

.jpg)

Figure 2.1 KPI Indicators

(3) Driving navigation

The start-up process of the sulfuric acid plant is complex and interlinked. Any oversight may bring safety risks. This function aims to promote the process-oriented and standardized operation of the driving process. It not only provides standardized guidance for skilled operators but also offers strong support for enterprises to accumulate experience and train new employees. The operation habits and management requirements of each chemical plant are different. We are committed to making every safe operation a unique digital asset of the enterprise, helping the enterprise build a sustainable and passed down "digital immortality". Click on "Start-up Safety Control Start" at the lower left corner, and you can fill in the real operation data step by step in the order of liquid sulfur conversion, drying absorption, waste heat recovery and boiler fan. The system is only allowed to perform the final device startup operation when all sections meet the preset startup conditions.

.jpg)

Figure 3.1 Driving Navigation

The subsequent version will also support custom configuration of device locations and driving conditions. Users can freely add, delete or modify relevant device and condition items in the driving navigation according to their actual process and management needs, truly achieving personalized and scalable intelligent driving guidance.

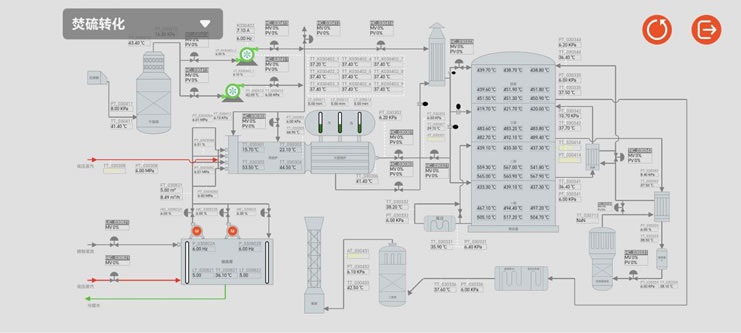

(4) Real-time monitoring

We plan to fully migrate the traditional computer-end section flow diagrams and DCS data to the mobile end, breaking the equipment limitations and truly achieving "handheld monitoring" - no matter whether you are in the central control room, on-site inspection or on a business trip, you can simply open your mobile phone to keep track of the operation status of the equipment at any time. The current effects presented by this function are all simulated data for reference only! Detailed data analysis capabilities will be launched in the future. Combined with the material balance function, not only can historical operation data be deeply mined and analyzed, but also the future operation trend of the device can be simulated and predicted, achieving forward-looking diagnosis and providing strong support for production optimization and management decisions.

Figure 4.1 Real-time Monitoring

(V) Other supplements

To further enhance the user experience, we continuously optimize and improve various functions of the APP. The homepage - Information Section has added an industry news and information column. Every week, we will push the latest industry trends, sulfur prices, import and export situations, etc. to you (reprinted from the original article of the News Express column of China Sulfuric Acid Network, and has been officially authorized by China Sulfuric Acid Network). Meanwhile, we have made multiple optimizations to the "Xiaoli Practice Questions" function: the types of questions are more explicit, and the question bank has added more carefully selected questions; Fixed several known issues to enhance the stability of the application.

The above is all the content of the update of the third-generation digital sulfuric acid APP this time! The release time of the APP will be announced in the Digital Sulfuric Acid communication group. To not miss the release of the new version and the latest changes, you can join the group to get the latest news! If you have any questions or better ideas during the usage process, you can also speak freely in the communication group. We sincerely look forward to your joining!

(VI) Method of Acquisition

The official way to obtain the Digital Sulfuric Acid APP is to search for "Digital Sulfuric Acid" in major app stores (supporting both Android and Apple platforms) and download and install it! Note: The third-generation digital sulfuric acid APP can be connected to the DCS system of your company's sulfuric acid plant to achieve digital management of the sulfuric acid plant. For more details, please follow our official account and contact us.