- The automatic condensate acid discharger contributes to the green development of sulfuric acid plants

The 400,000-ton phosphate ammonium and 200,000-ton sulfur-based compound fertilizer project of Hubei Yihua Chuxing Ecological Technology Co., Ltd. is a key project of Yihua Group to support the protection of the Yangtze River and promote industrial transformation. This project is based on the development concept of "green, low-carbon, circular and intelligent". The 800,000-ton sulfur-to-acid plant that is matched has adopted a number of innovative technologies to achieve intelligent and green production. Our company's independently developed automatic condensate acid discharger is honored to be applied in this device to solve the problem of unorganized waste gas emissions of condensate acid and enhance the environmental protection level of the production process. This equipment effectively reduces the escape of harmful gases by precisely controlling the automatic discharge of condensed acid, ensuring the stability and safety of the production process. Meanwhile, the application of this technology has further promoted enterprises' exploration in energy conservation, emission reduction and efficient resource utilization, contributing to the realization of the goal of green factories. In actual operation, the automatic discharge device for condensing acid has demonstrated outstanding stability and efficiency. It not only reduces the intensity of manual operation but also significantly improves environmental protection indicators, becoming a key link in the green upgrade of sulfuric acid plants.

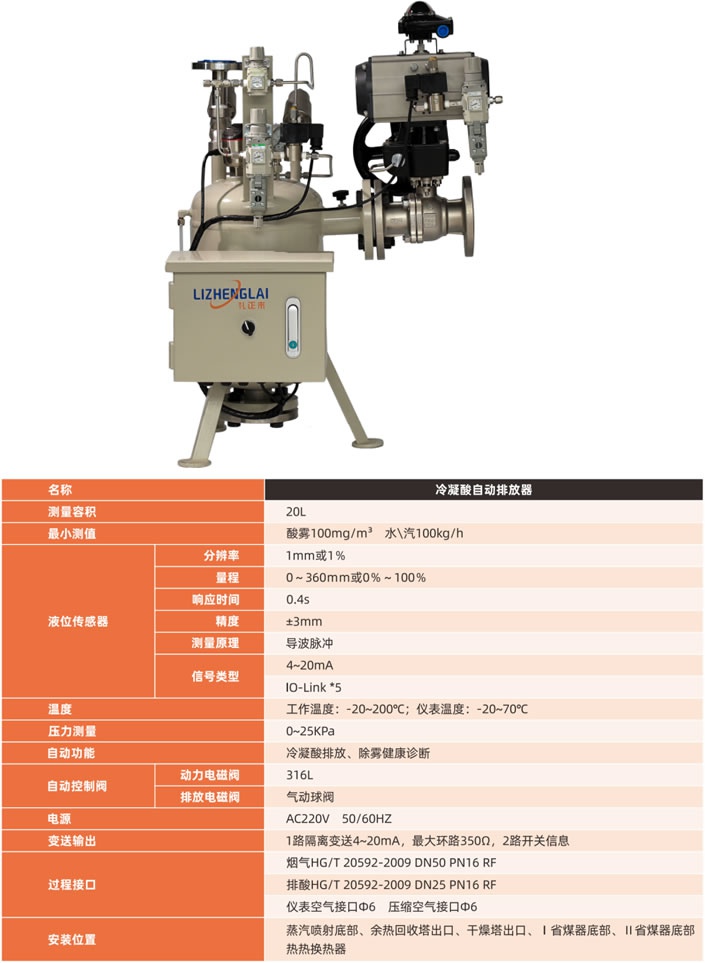

1. A condensate acid discharger tailored for sulfuric acid plants

The LSA-300 series condensate acid automatic discharger will provide a complete set of skid-mounted combined equipment specially designed for the closed and leak-free automatic discharge of high-temperature concentrated sulfuric acid in sulfuric acid plants. All materials of this discharger are made of special materials resistant to high-temperature concentrated sulfuric acid to ensure that it can meet strict safety and performance standards in harsh high-temperature acid environments.

1. It can be installed at the bottom of the steam jet, the outlet of the waste heat recovery tower, the outlet of the drying tower, the bottom of the coal container in Province I, the bottom of the coal container in Province II, and the heat exchanger to replace the traditional manual discharge and condensate acid tank.

2. When the amount of condensed acid generated by the device is abnormal, it can promptly detect and adjust the process parameters and identify device faults, thus avoiding significant shutdown losses for the device.

3. The automatic condensate acid discharger eliminates the safety risk of direct contact with sulfuric acid for operators and avoids the risk of sulfuric acid injuring people from the source. At the same time, it reduces the labor intensity of the operators.

4. It eliminates the blind spot of unorganized acidic gas emissions from the sulfuric acid plant, protecting the production environment and preventing equipment from being corroded by dilute acid.

2. Facilitate the green development of sulfuric acid plants

The 800,000-ton sulfur-to-acid plant of Chuxing Ecology has adopted a number of innovative technologies, aiming to build the current advanced automatic control sulfur-to-acid plant, while comprehensively enhancing production efficiency and environmental protection levels. Among them, the application of the LSA-300 series condensate acid automatic discharger, as a key link in green production, not only realizes the fully sealed, leak-free and automated operation of the condensate acid discharge process, but also significantly reduces human intervention and safety hazards. By precisely controlling the emission process, the device effectively avoids equipment corrosion caused by the accumulation of condensed acid and can promptly detect process fluctuations, thereby ensuring the continuity and stability of sulfuric acid production. The application of this innovative technology marks that the sulfuric acid plant has solved key problems on the path of green and intelligent development, setting a new benchmark for high-quality development in the industry. The full automation of condensate acid discharge and inspection has further set a model for high-quality green development in the industry.