- The manufacturing details of the high-efficiency sulfur gun ensure the long-term operation of the device

Preface

As one of the key core components in the sulfuric acid production unit from sulfur, the performance and quality of the sulfur gun directly affect the safety, environmental protection performance and long-term stable operation of the unit. According to statistics, during the operation of sulfuric acid production units from sulfur, the proportion of unplanned production halts caused by sulfur gun malfunctions is as high as over 30%. The main types of faults include insulation steam leakage, flow reduction caused by blockage, liquid sulfur leakage, gun body bending and low atomization efficiency.

The failure rate of the sulfur gun is significantly higher than that of other factors such as pump failure, equipment leakage and electrical and instrumentation failure, which leads to the shutdown of the equipment for maintenance. Due to the harsh operating environment of the sulfur gun, to reduce its failure rate, it is not only necessary to have a reasonable design but also to strictly control the quality of the manufacturing process. This can reduce the occurrence of faults in the sulfur gun during its operation, ensuring that the device can avoid production halts caused by sulfur gun malfunctions throughout its long operating cycle, thereby providing a solid guarantee for stable production and reducing economic losses for the enterprise.

The sulfur gun failure that caused the device to shut down

1. Strictly control raw materials

No high-quality product can do without high-quality raw materials. Sulfur guns operate in high-temperature and corrosive environments, so it is particularly important whether the raw materials of their gun bodies have high-temperature resistance and corrosion resistance. The high-efficiency sulfur gun manufactured by our company strictly selects high-quality 310S material as raw material. In the current context of fierce market price competition and severe internal competition, the phenomenon of passing off inferior goods as good ones often occurs in the market. To ensure that the materials of the high-efficiency sulfur guns manufactured fully meet the technical requirements, our company conducts 100% inspection on each batch of raw materials purchased. Meanwhile, to avoid the problem of material mixing during the manufacturing process, we also conduct 100% inspection on all the materials we prepare. Our company is equipped with advanced raw material inspection facilities, including Olympus Vanta series handheld spectrometers and Mitutoyo vernier calipers, ensuring the accuracy and reliability of the inspection results.

Olympus Vanta Series Handheld Spectrometer

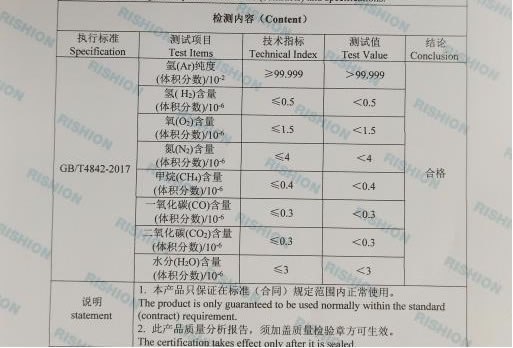

As the raw material of the high-efficiency sulfur gun is 310S high-nickel stainless steel, which has excellent heat transfer performance, to effectively reduce welding defects, argon arc welding technology is adopted throughout the entire manufacturing process of the high-efficiency sulfur gun. To reduce the introduction of oxygen and water vapor during the welding process, the shielding gas used in argon arc welding is 99.999% analytical grade argon.

2. Manufacturing details

2.1 Perfect quality management

Wang Xueyi is currently a quality management engineer in the company and holds a master's degree from Chongqing University of Science and Technology. She is mainly responsible for the company's production quality management system, covering the entire process from raw material management to finished product delivery from the warehouse. In every stage, she strictly adheres to the company's relevant quality management standards. Her rigorous management approach ensures the high quality standards of each sulfur gun.

2.2 Superb welding skills

Wang Shansong, a senior welding technician of the company, holds a special equipment operation certificate and has many years of welding experience. He has a solid theoretical foundation and rich practical experience. Since joining the company, he has handled the welding of over hundreds of sulfur guns. His superb welding skills have provided a solid safety guarantee for the qualified quality of each sulfur gun.

2.3 Quality Certification and Technical Standards

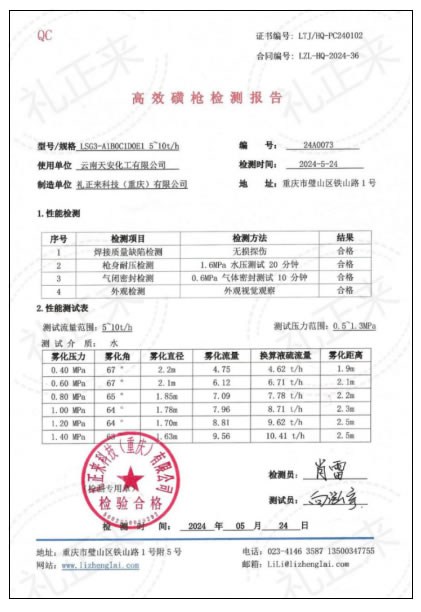

2.4 Performance Test Report

3. Manufacturing standards

3.1 Strict selection of raw materials

We use 6-meter stress-release precision 310S seamless steel tubes and cut them according to the specific length of each high-efficiency sulfur gun to ensure that the gun body of each high-efficiency sulfur gun is a whole tube without welds, thereby effectively reducing the leakage risk of the high-efficiency sulfur gun. Both the high-efficiency nozzle and its nozzle seat are integrally processed from 310S bar stock.

3.2 Strict control over manufacturing

The sulfur gun needs to be used for a long time in the alternating cold and hot environment of the sulfur-burning furnace. To ensure that the weld seam does not fail or leak, the welding quality is of vital importance. To reduce weld failure and leakage, during the welding process of the high-efficiency sulfur gun assembly, we strictly follow the "Technical Standards for the Manufacture of High-Efficiency Sulfur Guns". Each weld seam is filled with high-purity argon gas to displace the gun body, ensuring that the material is not oxidized during the welding process and avoiding the formation of pores or defects. Due to its fast heat conduction speed, 310S material is prone to significant thermal stress deformation during the welding process. To effectively reduce the deformation caused by welding thermal stress, after each weld seam is completed, we will patiently wait for it to cool down naturally before proceeding with the next weld seam welding operation.

The welding quality of the connection between the liquid sulfur tube and the outer jacket of the gun body and the nozzle seat is the key to ensuring that the sulfur gun does not leak throughout its lifetime. To ensure that the welding quality at this position of each high-efficiency sulfur gun is consistent and defect-free, we adopt fully automatic welding, which is controlled by welding technicians to ensure the welding quality.

The high-efficiency sulfur gun is installed in the narrow space of the sulfur burning furnace. Every time the device undergoes major maintenance, the sulfur gun needs to be disassembled. Due to the weak expansion joint of the high-efficiency sulfur gun, it is prone to being struck during disassembly. Therefore, we have designed an expansion joint protective cover and an axial fixing rod.

There are over 150 high-efficiency sulfuric acid guns in service at sulfuric acid plants around the world