- Rapid measurement of sulfur dioxide in converters - Trial appointment for chromatographic analyzer is now open for recruitment

I. Current Measurement Methods

The iodine solution method is currently the main approach for measuring the SO2 concentration in each section of the converter in the sulfuric acid industry. However, during the sampling process, the gas cools rapidly in the sampling tube, and its temperature drops quickly below the dew point, causing SO3 in the gas to combine with water to form acid mists. Due to the overly rapid cooling rate of the gas, the generated acid mist has an extremely small particle size and a large number of particles. When gas passes through the reaction tube in the form of bubbles, these tiny acid mist particles float within the bubbles, hindering the diffusion of SO2 molecules and preventing some SO2 molecules from reaching the gas-liquid interface.

For the gas at the outlet of each section of the converter, due to the high concentration of SO3, in addition to combining with the water in the gas to form acid mists, SO3 will also react with the water evaporated from the surface of the bubbles to further generate acid mists. These acid mists accumulate in large quantities on the surface of the bubbles, seriously blocking the diffusion of SO2 molecules to the gas-liquid interface. Therefore, the influence of SO3 in the outlet gas of each section of the converter on the analysis results of the iodine solution method is particularly significant, resulting in the measurement results generally being lower than the actual values and having poor repeatability.

The analysis process of the iodine solution method is shown in the figure. During this analysis process, there were too many pipelines on the experimental operation table and the equipment was placed unreasonably, resulting in limited controllable space. These problems seriously affected the analysis process of the operators and interfered with the accuracy of the experimental data results. In addition, during the sampling and analysis process, a large amount of acidic and toxic gases are often leaked out. This not only pollutes the environment but also causes corrosion to production equipment. Long-term exposure even poses a threat to the life and health of analysts.

Due to the lack of precise and controllable flow and pressure conditions in the analysis process of the iodine solution method, it often leads to the inability of analysts to obtain accurate analysis results and causes a large amount of acidic and toxic gas leakage, which has a serious impact on the physical health of analysts. The problem of unorganized gas leakage during the analysis process is particularly prominent. According to statistics, when a sulfuric acid plant conducts a segmented conversion rate analysis of the converter throughout the year, it emits approximately 2,800 cubic meters of acidic and toxic gases into the environment, which is equivalent to about 1.4 tons of sulfuric acid per year. It can be seen from this that the iodine solution method for analyzing SO2 not only seriously hinders the green development of the sulfuric acid industry, but also brings huge health risks to analysts.

Ii. Rapid Chromatographic Analyzer

In response to the challenge of measuring SO2 in converters, Lizhenglai Technology has developed the LAD120 rapid gas chromatography analysis system. This system is specifically designed for the measurement of SO2 in converters of sulfuric acid plants and can achieve rapid, accurate and emission-free chromatographic analysis. The LAD120 integrates catalyst conversion rate and heat exchanger leakage detection, making it a professional analysis system. This system can help factories keep track of the changes in the segmented conversion rate in real time, guide operators to adjust process parameters promptly, enhance the energy efficiency of the equipment, reduce SO2 emissions, and completely change the passive situation in sulfuric acid production where there is a lack of rapid analyzers to measure the segmented conversion rate.

In addition, LAD120 can also assist factory managers in monitoring the health status of converters and whether heat exchangers are leaking in real time, promptly and accurately identifying the leakage points and leakage rates of converters and heat exchangers, and arranging reasonable plans for equipment maintenance, thereby reducing economic losses. Through the big data analysis of the segmented conversion rate, this system provides a scientific basis for each catalyst screening and filling, effectively avoiding the increase in operating energy consumption and catalyst waste caused by excessive catalyst filling. At the same time, it also prevents insufficient catalyst filling from failing to achieve the expected effect, thereby reducing the pressure of environmental protection emissions and avoiding the increase in the number of equipment maintenance due to improper maintenance plans, which would cause significant economic losses to the enterprise.

The application of the LAD120 rapid chromatography analyzer has avoided the measurement errors of the traditional iodine solution method. It features good repeatability, high measurement accuracy, fast speed, simple operation and no flue gas emissions. It is an environmentally friendly system. It will provide users with analysis and optimization solutions for issues such as thermal efficiency, conversion rate, heat exchanger leakage, and system resistance throughout the entire life cycle of the device, significantly enhancing the economic efficiency of the entire life cycle of the device.

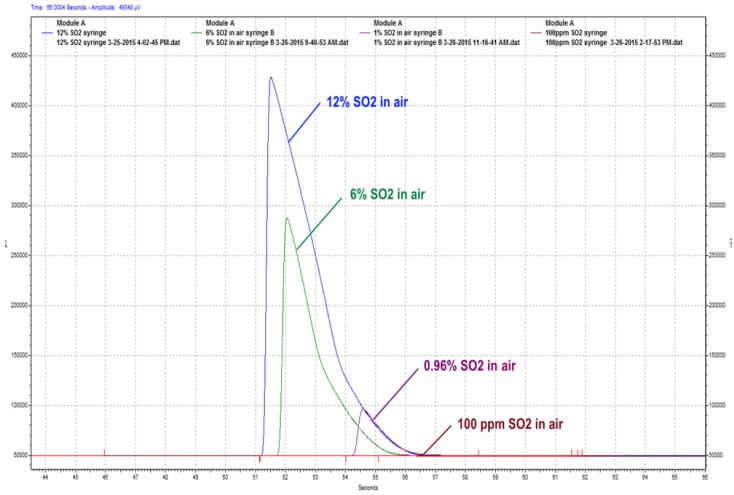

(譜圖)

The following figure shows the pre-conversion rate in the sulfur-burning furnace calculated by measuring the concentration of a section of the inlet. The continuous multiple measurements of the "3+1" two-rotation and two-absorption 400kt/a sulfur-sulfuric acid plant have stable repeatability of the measurement data, and the chromatographic analyzer has stable performance during continuous use.

Iii. Functions

1. Measurement of the segmented conversion rate of the converter

Each measurement data can be obtained in just 60 seconds. Import the data into the sulfuric acid health analysis system. The system will automatically calculate the balanced conversion rate of each section and store the data for big data analysis. This provides support for the screening and catalyst loading schemes for the planned maintenance of the device in the later stage.

2. Heat exchanger leakage inspection

During the production process of sulfuric acid, as time goes by, the health condition of heat exchange equipment will gradually decline, and the risk of leakage will also increase accordingly. Therefore, timely monitoring of the health status of heat exchange equipment is crucial for ensuring the system's conversion rate. By comparing the changes in SO2 concentration at the low-pressure inlet and outlet of the heat exchange equipment, if the SO2 concentration increases, it indicates that there is a leakage in the device. With the help of the sulfuric acid health analysis system, concentration changes can be analyzed and the leakage rate can be precisely calculated.

.jpg)

Iv. Advantages

1. Enhance the operational efficiency of the sulfuric acid plant to create greater economic value; Shorten the maintenance time, extend the maintenance cycle, and promptly identify potential equipment hazards, thereby reducing the losses caused by the shutdown of the sulfuric acid plant.

2. The rapid one-time measurement of multiple components (CO, CO2, SO2, H?S, HC?, etc.) in the sulfuric acid device can measure a wide range of complex samples with high percentage and low ppm components, and can measure as low as 1ppm

V. Trial recruitment is in full swing

.jpg)

We are now recruiting 20 trial devices for SO2 measurement of rapid chromatography analyzer converters nationwide. The number of spots is limited and will be allocated on a first-come, first-served basis. Our company will provide professional guidance throughout the process to ensure the correct use of the analyzer.

Contact person: Yang Haidong

Tel: 13500347755

Email: yanghd@lizhenglai.com

Address: No. 88, Innovation 2nd Road, Daxing Town, Bishan District, Chongqing City, Annex 12