- The fourth-generation high-efficiency sulfur gun - with a new online cleaning function added

I. Preface

The sulfur gun, as a key component in the sulfur-to-acid production plant, its operational efficiency and quality directly affect the safety and economic benefits of the entire plant. At present, 156 high-efficiency sulfur guns of Lizhenglai Technology have been put into use in the sulfuric acid plant, among which the longest one has been in use for three years. As the operation time of the device increases, some users have reported that the pressure of the high-efficiency sulfur gun gradually rises after 18 to 20 months of operation. In addition, there are also other users who have not used the high-efficiency sulfur gun reporting clogging problems with the sulfur gun. Based on user feedback and research on the usage of the sulfur gun, Li Zhenglai Technology has found that the online cleaning function of the sulfur gun is of vital importance. Online cleaning can effectively solve the problem of sulfur gun blockage caused by foreign substances, iron sulfide and other impurities, thereby avoiding production halts due to blockage faults and reducing the safety risks brought by replacing the sulfur gun. This not only ensures the long-term stable operation of the device, but also provides a strong guarantee for the continuous production of the enterprise and the reduction of economic losses.

Two. Four core technologies of the fourth-generation high-efficiency sulfur gun

1. Gun body uniform temperature technology

When the sulfur gun is installed in the sulfur burning furnace, the gun body will undergo expansion of the metal material due to high-temperature roasting. The gun body is made of 310S stainless steel, and the temperature difference during operation and after parking can reach approximately 500℃. According to the expansion formula, the expansion of the gun body after parking is approximately 10 to 15 millimeters. If the heat preservation steam inside the gun body is unevenly distributed, it will cause a temperature difference on the upper and lower sides of the gun body, thereby resulting in different expansion amounts and ultimately causing the gun body to bend upward. For this reason, we have independently developed the gun body temperature equalization technology. This technology can ensure that the temperature of the upper and lower parts of the sulfur gun body remains consistent and the expansion amount is the same when the sulfur furnace is in operation or shut down, thereby effectively solving the problem of gun body bending.

2. High-efficiency atomization technology with large flow channels in the nozzle

As the liquid sulfur pipelines or storage tank areas are usually made of carbon steel, the iron sulfide produced by the corrosion of liquid sulfur may mix into the liquid sulfur and be transported to the sulfur incineration furnace, causing the sulfur gun to get clogged during operation, which may lead to the shutdown or reduction of production in the facility. The high-efficiency sulfur gun nozzle adopts a large direct-through flow channel technology (with a flow channel area of up to 376mm²) and is equipped with an anti-clogging cone, which can effectively pass through iron sulfide and prevent clogging. In addition, this nozzle is equipped with a straight-through flow channel speed-increasing atomization technology. Its mist torch is in the form of a rotating solid cone. This design enables the stratified combustion of sulfur mist, effectively avoiding the sublimation of sulfur and the overheating of the sulfur incineration furnace caused by the deflagation of hollow sulfur mist on the inner surface of the furnace. The nozzle flow channel is made of gold composite material, which can effectively solve the corrosion problem of iron reacting with sulfur to form iron sulfide at high temperatures, thereby significantly improving the durability of the nozzle.

3. High-diameter pressure-bearing welding technology

The device often stops due to steam or liquid sulfur leakage from the sulfur gun. The main reason is that the sulfur gun is made by welding three layers of jacketed tubes. As the sulfur gun is in a high-temperature environment and the diameters of each layer of the jacket tubes are different, the stress will be concentrated at the weak points of the welding after thermal expansion. If there are minor defects such as slag inclusion, pores, and hydrogen cracks at the welding position, it will lead to stress concentration, which in turn causes welding failure and results in steam or liquid sulfur leakage. Therefore, adopting effective welding techniques is the key to solving the problem of sulfur gun leakage. The high-efficiency sulfur gun adopted high-diameter pressure-bearing welding technology for the weld seams in the sulfur incineration furnace and was protected with 99.999% high-purity argon gas, achieving single-sided welding and double-sided forming. In addition, the weld seams undergo 100% non-destructive testing, effectively avoiding welding defects and design flaws, thereby ensuring the durability and reliability of the high-efficiency sulfur gun.

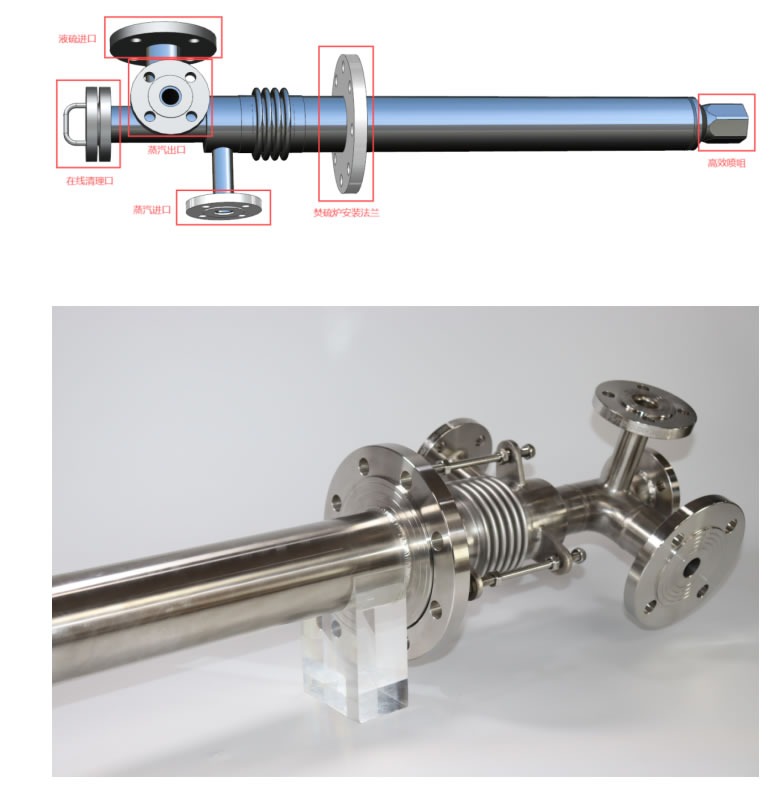

4. Online cleaning technology

Sulfur acid-making plants often have their sulfur gun nozzles clogged by foreign substances, iron sulfide and impurities, which forces the plants to stop and replace the sulfur guns. Each shutdown causes at least a 4-hour production interruption. Therefore, the online cleaning technology of the sulfur gun is particularly important. We have achieved the online cleaning of the high-efficiency sulfur gun by optimizing its structure. After the structural improvement, since the liquid sulfur inlet is located on the side of the sulfur gun, when disassembling and installing, only the bolts need to be directly removed to take off the sulfur gun. There is no need to disassemble part of the liquid sulfur pipeline of the sulfur burning furnace as in traditional sulfur guns to remove the sulfur gun from the furnace. This design offers a more convenient installation and disassembly method, reducing the installation time of the sulfur gun from 2 hours to 30 minutes. The following is a schematic diagram of the fourth-generation online cleaning high-efficiency sulfur gun: